The Ultimate Guide to Choosing CMMS Software: 6 Critical Factors for 2025

Efficiency, ESG, and cost pressures in today’s environment are driving many organizations to rethink their approach to delivering maintenance services and selecting the right CMMS software. Whether you’re an asset stakeholder or a service provider, the pressure is on to deliver maintenance at a lower cost, higher quality, and better overall efficiency.

Choosing the right CMMS software can transform how your organization manages maintenance operations. Below, we explore six critical factors to consider before you make your investment decision.

1. IoT Integration: Turning Data into Predictive Power

What about IoT? Will the collection of sensor data help you become predictive and avoid costly hazards?

Yes — implementing IoT can help predict and avoid costly hazards by providing vital data for early problem detection in assets. This enables predictive analytics on critical asset conditions. However, IoT requires a significant initial investment in hardware, networking, and asset data expertise. A successful IoT-enabled CMMS depends on high-quality data and robust technical logic.

Pro tip: Work with a CMMS provider that supports seamless IoT integration and has proven experience with data-driven maintenance environments.

2. AI-Enabled CMMS: Smarter Decision-Making

AI can help in decision-making and automation, right? Absolutely. Like IoT, AI can be incredibly valuable for managing complex maintenance requirements and uncovering hidden operational threats.

While some CMMS software offers built-in AI for scheduling and job distribution, tasks like asset failure prediction and smart inventory management often need custom models. Effective AI requires training on your specific operational data to deliver meaningful insights.

Recommendation: Partner with a vendor that understands how to train AI models on your historical maintenance data for the best results.

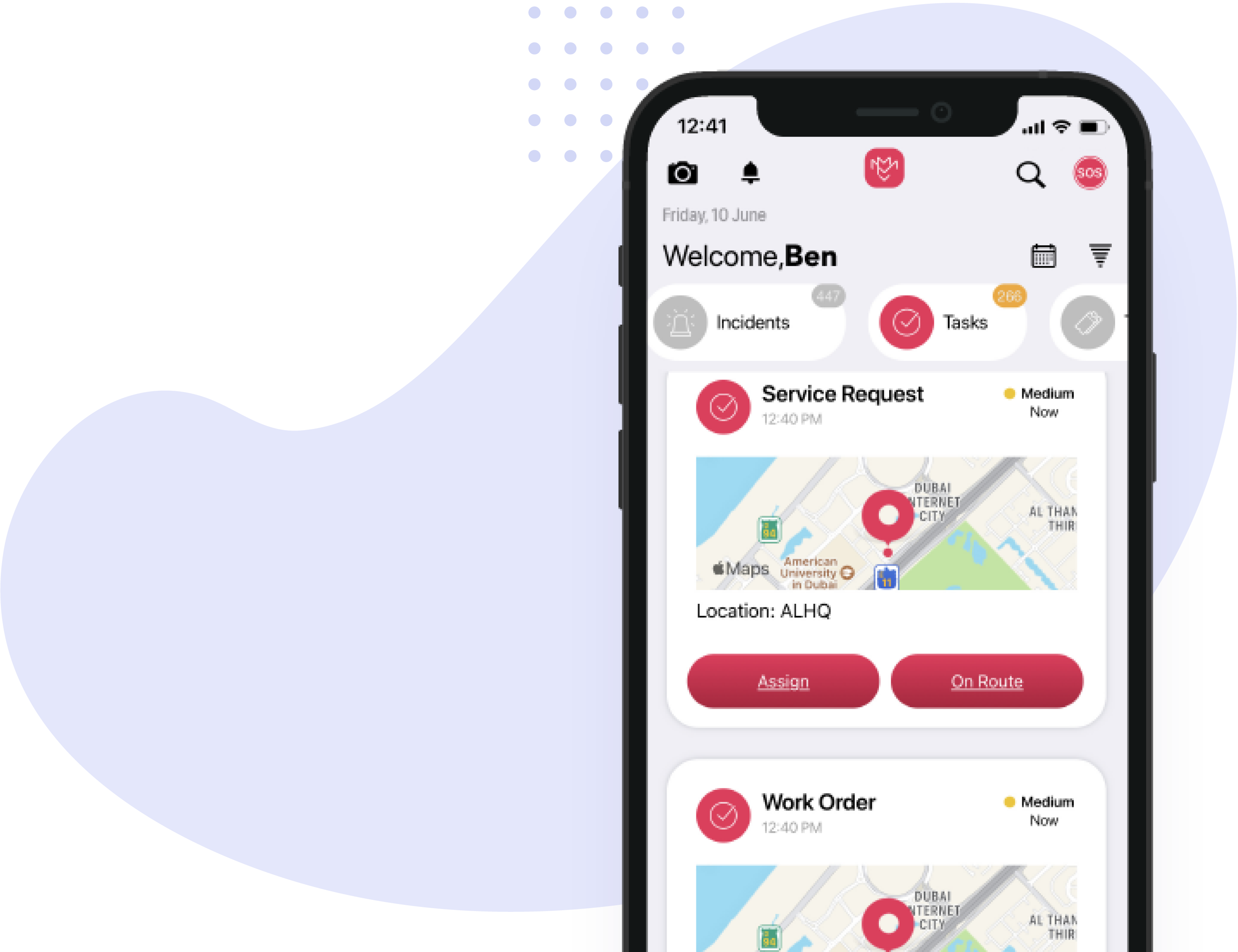

3. Mobile-First Maintenance: Empowering Your Workforce

Is mobile access really important? Yes, indeed. Mobility offers substantial advantages in cutting costs, boosting productivity, and achieving ESG goals.

Mobile CMMS solutions reduce administrative burdens for frontline technicians, enable on-the-go access to asset data, and ensure accurate information capture at the source. While onboarding and training may take time, the benefits of mobility far outweigh the costs.

Best practice: Choose a mobile-enabled CMMS that provides offline functionality and supports real-time updates for field teams.

4. Cloud-Based CMMS: Lower TCO, Higher Agility

Is on-premise still better for control and privacy? It depends — but for most organizations, cloud-based CMMS platforms deliver greater long-term value.

Cloud solutions offer lower total cost of ownership (TCO), faster deployment, built-in AI capabilities, and continuous updates. While on-premise systems may appeal for perceived data privacy, the flexibility and scalability of cloud platforms generally outweigh those concerns.

Tip: Work with a CMMS vendor that can address your data residency and compliance requirements effectively while providing cloud reliability.

5. Predictive & Proactive Maintenance: The Path to Zero Downtime

Predictive maintenance is the ultimate goal for modern maintenance teams — delivering significant savings and performance improvements. But achieving it requires several building blocks: a fully digital landscape, IoT-connected assets, a connected workforce, rich historical data, and a well-trained AI model based on solid business logic.

It’s a journey that demands more than software alone — it requires strategic investment in process, technology, and data maturity.

Next step: Learn how organizations use predictive maintenance with MIMS to reduce downtime and optimize asset performance.

6. Data-Driven Maintenance: Insights that Drive Performance

What does data-driven maintenance mean? It means making operational decisions based on accurate, real-time data collected from human input, IoT devices, or AI analytics.

Even without IoT or AI, a CMMS can be data-driven if it captures and structures accurate maintenance information. Data-driven systems enable better resource scheduling, technician dispatching, cost control, and inventory optimization. A strong CMMS doesn’t just collect data — it helps you act on it.

Action point: Evaluate how well your CMMS captures, visualizes, and reports key maintenance metrics to support smarter decision-making.

Conclusion: How to Choose the Right CMMS Partner for Sustainable Efficiency

Choosing the right CMMS software involves understanding your organization’s specific needs and balancing features such as IoT integration, AI capabilities, mobile access, cloud-based deployment, predictive maintenance, and data-driven insights. Each offers unique benefits and challenges — the key is aligning them with your strategic goals.

Work with a vendor who can adapt to your operational environment, provide end-to-end implementation support, and evolve with your digital transformation journey. The right CMMS partner will not only improve maintenance efficiency but also strengthen ESG performance, compliance, and customer satisfaction.

FAQs

What is a CMMS and how does it help?

A CMMS (Computerized Maintenance Management System) is software that streamlines maintenance operations, tracks assets, schedules preventive work, and reduces downtime by automating maintenance processes.

How do AI and IoT improve CMMS software?

AI and IoT enhance CMMS capabilities by collecting and analyzing data from assets, enabling predictive maintenance, better scheduling, and faster response times.

Is a cloud-based CMMS better than on-premise?

Yes, for most organizations, cloud CMMS provides greater flexibility, lower costs, faster implementation, and continuous feature updates, while maintaining high data security standards.