Many businesses across various industries rely on well-maintained infrastructure to conduct their operations. Despite it not being their primary focus, the upkeep and maintenance of infrastructure have become a significant aspect of doing business. This is particularly true for industries such as maritime, aviation, telecom, retail, and manufacturing. However, as infrastructure maintenance has become increasingly complex and safety standards and regulations have risen, managing maintenance needs has become a significant challenge for companies.

To tackle this issue, some companies have outsourced their maintenance to third-party service providers while others have developed internal teams to manage their maintenance needs. However, companies in both scenarios incur substantial costs to keep their machines and facilities running efficiently.

Unfortunately, many companies do not pay enough attention to the way in which maintenance is delivered, assuming it is not a core aspect of their business. This view can result in significant cost increases and inefficiencies, leaving businesses exposed to regulatory breaches. Moreover, outdated paper-based approaches, lacking data support, are often used to manage the critical function of maintenance, failing to provide insight on the true cost of maintenance and leaving gaps that can be exploited to reduce costs.

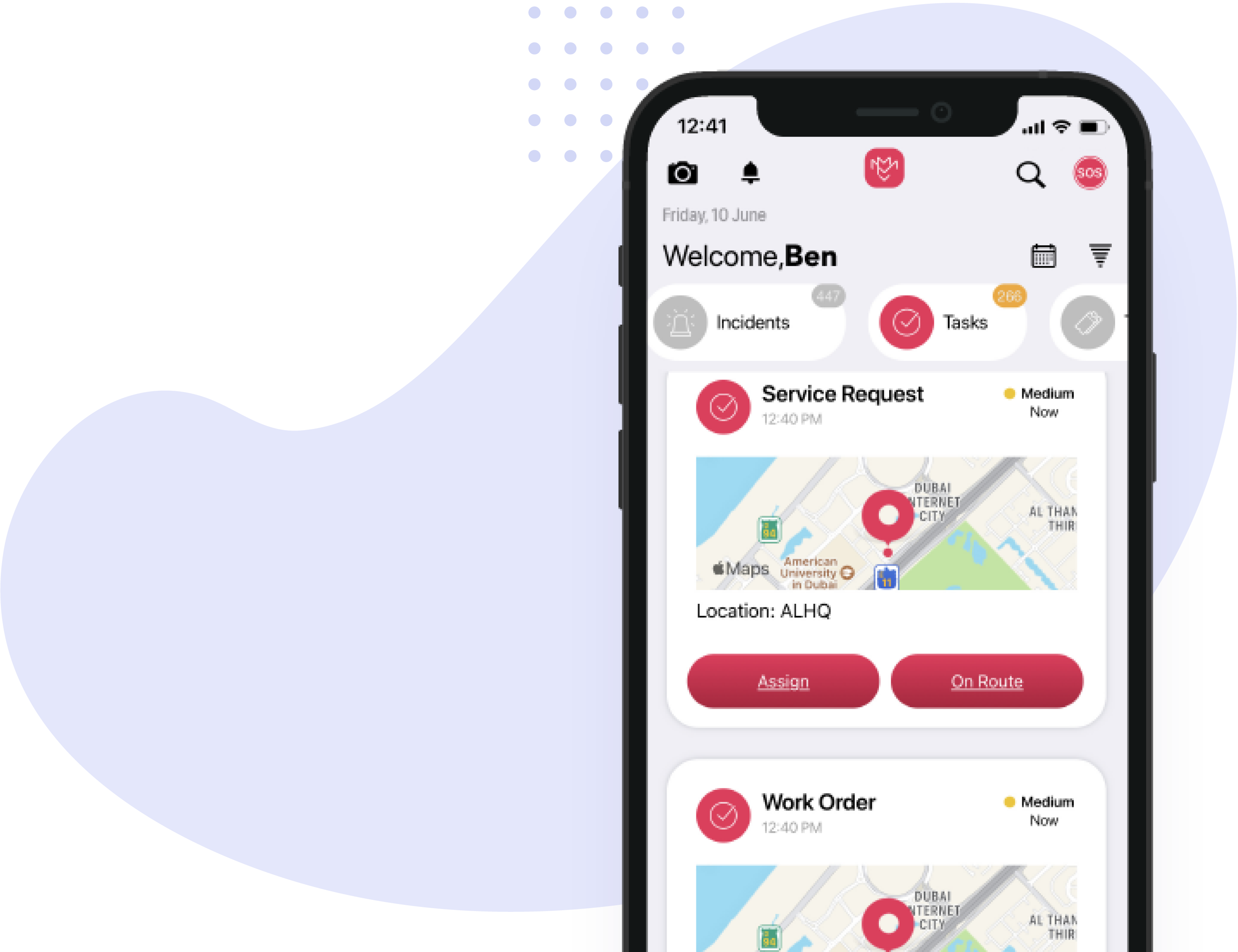

For instance, labor, material, and fuel costs are often mere estimates, while the absence of data on cost-effective resources or nearby material stores can prolong repair time. However, modern maintenance solutions can provide valuable insights that can help businesses become more proactive and predictive in their maintenance approach, identifying potential cost savings of up to 25% or 30%. These solutions can optimize the distribution of work based on factors such as skill, proximity, fuel, and available materials, helping companies deliver jobs more cost-effectively. Moreover, real-time cost capture can expose working gaps and offer rectification options based on real-time data.

Whether a company outsources its maintenance or manages it internally, modern technology-based maintenance models are vital to achieving positive returns and cost savings.